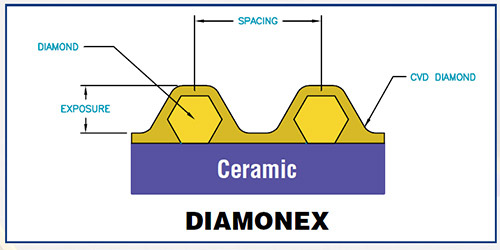

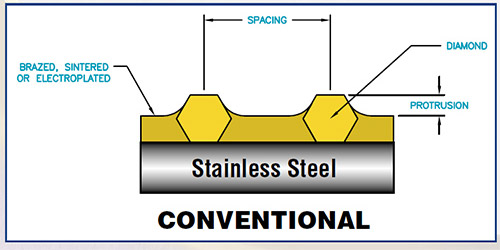

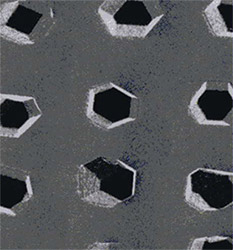

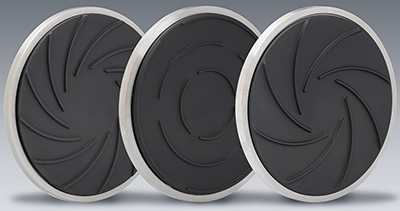

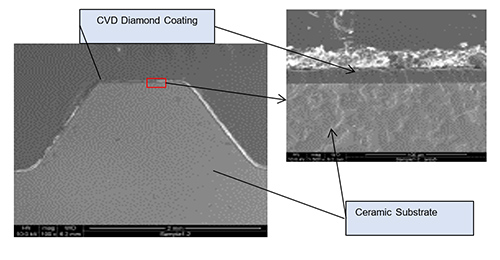

Out of several hundred steps in the semiconductor chip manufacturing process, Diamonex has specifically focused on engineered pad conditioners for the CMP process steps. CMP is a critical process in wafer fabrication and is used multiple times during the manufacture of semiconductor wafers. It is a precise, challenging, and critical step to the improved performance of the final device. Yield degradation is a critical concern for the process engineers and defects on the surface of the wafers can cause significant problems. Our CVD Diamond creates a working surface that provides less variation, maintains uniform pad wear, and extends pad life.

The conditioner design influences the texture of the pads, and this in turn affects yield and productivity in the chip fabrication process. As electronic devices become ever smaller and integrated circuits become increasingly complex, conditioning materials must evolve to meet new demands in the market.

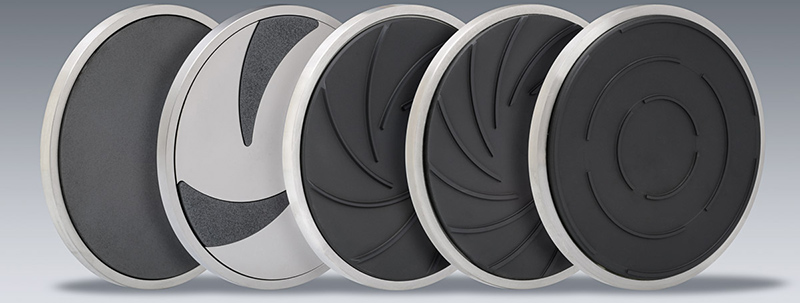

With over 46 patents granted, Diamonex® is committed to excellence in its field and has dedicated resources to developing more advanced products to fit a constantly evolving market. We are able to customize your conditioner to meet soft, medium, or hard pad requirements, as well as working with a variety of slurry combinations.

To review test data pertinent to your specific CMP process conditions, contact us today.

An Engineered Solution for Controlling Pad Texture

An Engineered Solution for Controlling Pad Texture